PAT testing stands for portable appliance testing and is a legal requirement to producers and companies to ensure that the electrical appliances pose no safety risk to the users of the machine. Even though it is a legal requirement, there is no strict regulation or law and manufacturers commonly perform the testing in-house to guarantee the safety standards for their great and the customers’ well being. PAT tester are individuals who are qualified to carry out these tests although they do not have to have an electrical background, such as engineering of being a practising electrician. The testing process is sort of upkeep and obligation carried out to discover malfunctioning products and determine what the problem is intentionally. PAT testing, since it is quite ambiguous and largely dependent on the desire of producers and companies to provide safe appliances, is made a large part of the simple physical inspection. It’s stated that the huge majority of the process of the testing is a simple physical inspection searching for obvious defects. Go to the following site, if you are searching for additional information on fixed wire testing.

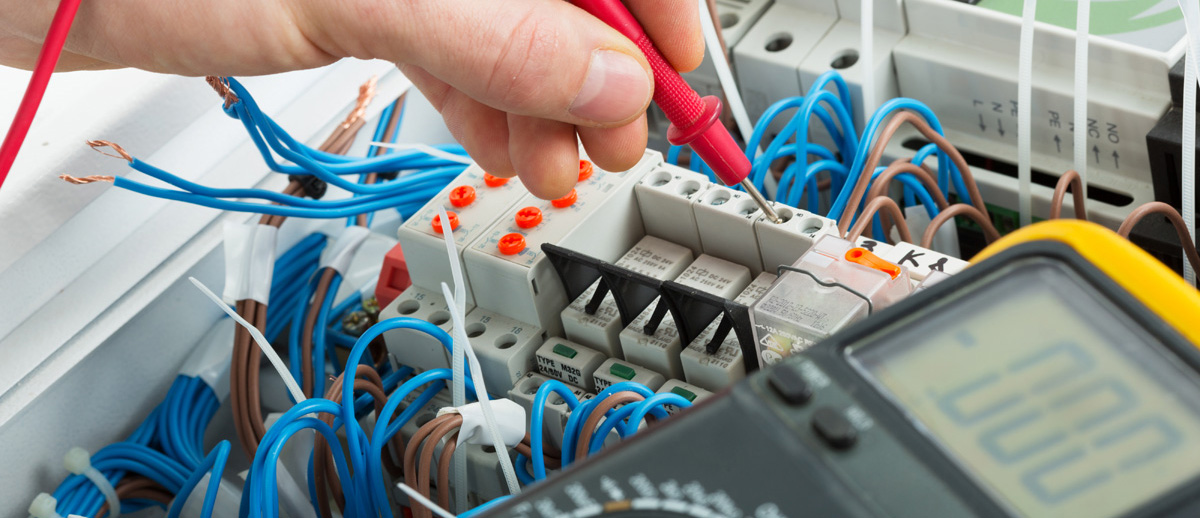

These obvious defects are power cords that are torn and have exposed wires, plugs with bent or broken prongs, broken switches or exposed electrical components. This section of the testing might appear obvious and simple but it is required, and the simple fact is that most problems can be discovered via this type of inspection. A PAT tester is a small machine, portable and lightweight, which assesses various electrical components of an appliance and indicates whether the appliance is properly working and if it may pose a safety risk. An example of this is wire insulation. All wires have insulation that’s resistant to the electricity being carried through the wire; this allows the user to handle or touch it without being shocked or electrocuted. The PAT tester can ascertain if the insulation is sufficient to the cable it surrounds. If it’s not, this is an obvious threat. The PAT tester in the PAT testing process may also gauge the polarity of the electrical unit, to make certain that electrons are following the designated path, such as negative to positive, and in the case of alternating current that this is working properly.

These obvious defects are power cords that are torn and have exposed wires, plugs with bent or broken prongs, broken switches or exposed electrical components. This section of the testing might appear obvious and simple but it is required, and the simple fact is that most problems can be discovered via this type of inspection. A PAT tester is a small machine, portable and lightweight, which assesses various electrical components of an appliance and indicates whether the appliance is properly working and if it may pose a safety risk. An example of this is wire insulation. All wires have insulation that’s resistant to the electricity being carried through the wire; this allows the user to handle or touch it without being shocked or electrocuted. The PAT tester can ascertain if the insulation is sufficient to the cable it surrounds. If it’s not, this is an obvious threat. The PAT tester in the PAT testing process may also gauge the polarity of the electrical unit, to make certain that electrons are following the designated path, such as negative to positive, and in the case of alternating current that this is working properly.

Any electrical unit with continuity issues is a safety risk that is serious and the device will malfunction. Voltage can be measured with the device to be certain the specification on the label of what voltage the unit runs off or delivers is truly what is happening. If that isn’t accurate, the machine is not working properly and is a danger. The issue will have to be repaired or the machine lost. This process is in part a goodwill gesture between government requirements and producers products. Again, since there is no strict law and regulation, really just a simple statement that mobile appliances must not pose a safety threat or concern, it’s reflective of producers and companies really concerned with the purpose of their product and customer and employee safety. PAT testing, portable appliance testing, is designed to maximise safety in these machines and make sure machines are functioning properly.